Liquids

November 25, 2021 2021-12-05 9:51Liquids

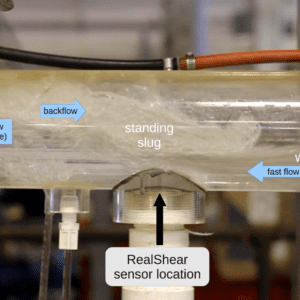

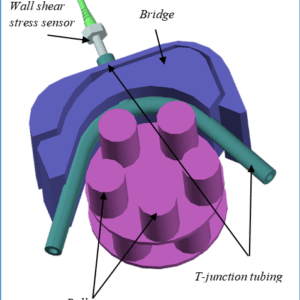

If the medium is continuous and flows freely, that is it conforms to the shape of the container and retains constant volume, it is usually referred to as a liquid. Accurately tracking liquid flows during a manufacturing process when materials have different states or phases ( such as gas and liquid) or different chemical properties within the same state, or phase ( liquid-liquid processes such as oil droplets in water) is critical. Such types of processing plays a major role in a large number of industries, such as food and beverage, health and beauty, oil, paint and lubrication, chemical, pharmaceutical, and many other. Transportation of liquids along pipes and other conduits is also important in these industries, and especially important in oil, gas and hydrocarbon transportation.

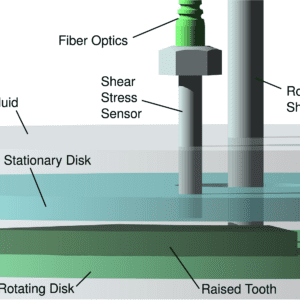

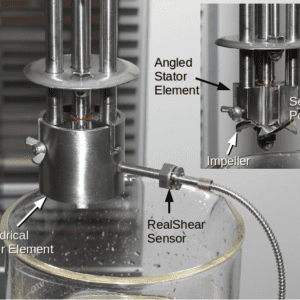

Rheological properties of liquids are usually described by viscosity which for non-Newtonian fluids is a function of flow velocity. Another important characteristic for most liquid processing applications is shear rate or fluid velocity gradient. For many application, including bio-processing, it is important to know the forces or shear stresses exerted on the liquids by the walls or agitator blades of the processing equipment.